-

gyratory crushers chambers

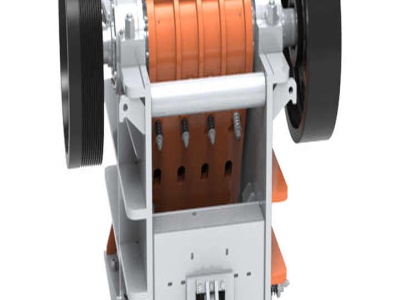

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

Get Price -

Gyratory Crusher an overview | ScienceDirect Topics

Gyratory crushers are principally used in surfacecrushing plants. The gyratory crusher (Figure ) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve. The spindle is suspended from a "spider" and, as it rotates, normally between 85 and 150 rpm, it sweeps out a ...

Get Price -

Primary Crusher Components | Crusher Mills, Cone Crusher ...

Crusher – Wikipedia, the free encyclopedia. The crusher's components are of high strength design to accept high power draw. . Gyratory crushers can be used for primary or secondary crushing.

Get Price -

CE Engineering Replacement Gyratory Crusher Parts

When it comes to Replacement Gyratory Crusher Parts, CE has been crushing the market for decades. If you demand the peace of mind that comes with ISO 9001certified, fullyguaranteed and warranted replacement parts for your gyratory crusher, your search ends with CE Engineering your replacement Gyratory Crusher Parts ONESTOP SHOP.

Get Price -

New Used Primary Gyratory Crushers for Sale | Crushing ...

Savona Equipment is your source for New, Used, and Reconditioned Gyratory Crushing Equipment of many types and brand for large primary ore crushing, secondary, and tertiary fine material as well as complete aggregate gyratory crushing lines. All our refurbished gyratory crushers will be completely disassembled and inspected.

Get Price -

Primary Crusher Wear Parts ME Elecmetal · Global ...

Our full range of products and services for primary crushing includes wear components for gyratory and jaw crushers: Gyratory crusher wear parts: • Concaves • Mantles • Under crusher parts • Rim liners • Spider caps and arm guards • Epoxy backing material • Chamber optimization • Oversize mantles design

Get Price -

Premium Crushing Chambers Flexifeed Mining

Sandvik Premium crushing chambers is an innovative, tested and patented range of high performing crushing chambers. Besides the undeniable benefits this premium range offers we have combined it with a high availability and made all sizes available...

Get Price -

Asphalt Mix Gyratory Press | Geneq

Asphalt mix gyratory press for civil engineering. Discover our gyratory compactors, mixers, polishing machines and many more. Find your products at Geneq.

Get Price -

gyratory crusher hydroset system | Mobile Crushers all ...

Jun 23, 2013· gyratory crusher hydroset system Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing ...

Get Price -

ALLIS CHALMERS CRUSHERS | Crusher Mills, Cone Crusher, Jaw ...

allis chambers superior gyratory crusher. allis chalmers crusher. Allis Chalmers Hydrocone, Gyratory Crushers, Superior Allis Parts . ESTABLISHED 1960. Contact us for complete listing of Crusher .

Get Price -

Crushers QueensMineDesignWiki

There are several types of crusher that are used in underground mining operations. The most common types of crushers are the gyratory crusher, the jaw crusher and the cone crusher. The technology and selection criteria will be discussed in section four. Post Crushing. After the ore is crushed it moves in to a chamber known as the ore bin.

Get Price -

Gyratory Crusher (KG model)|Crushing/Grinding ...

If the crusher has stopped during the crushing operation.It is necessary to remove the raw material from the crushing chamber.Thanks to the hydraulic system, ores in the crushing chamber can be discharged by lowering the crushing head for immediate restarting. Heavy Duty Spider Bearing

Get Price -

How does a Gyratory Crusher Works Mineral Processing ...

May 19, 2013· In this video we will see what are the basic features of a Gyratory Crushers. Gyratory Crusher are used in Mineral Processing Industry for size reduction of Run off Mine (ROM) materials to size ...

Get Price -

ESCO Corporation | Gyratory Crusher Wear Parts

Gyratory Crusher Wear Parts. ESCO concaves are larger than the competition, for fewer pieces to handle – resulting in less time to remove old segments and install new ones. Larger castings generally have a lower cost per pound, resulting in a lower price per pound in production.

Get Price -

Kreiselbrecher – Weil Brechertechnik GmbH

Wide choice of crushing chambers ... following high capacity jaw or gyratory primary crushers. The only difference between this and other types is the large feed opening of their crushing chamber, which for some sizes is equipped with reversible concaves. All the parts of the crusher, the crushing chamber excepted, are interchangeable and standard.

Get Price -

Optimization of primary gyratory crushing at Highland ...

This thesis presents the work done in a collaborative research project between the University of British Columbia and Highland Valley Copper. The research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process. Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device. Data from ...

Get Price -

cone vs gyratory crusher

Crusher Wikipedia, the free encyclopedia. A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone...

Get Price -

Gyratory Crusher_CITIC Heavy Industries

Gyratory and Cone Crushers CITICIC manufactures every component at our own works other than electric motors. Our Gyratory Crusher designs range from 110165 (4265) up to 152287 (60113) and can handle feed sizes up to mm and capacities to

Get Price